旋转轴唇形密封圈的发展历史与展望(英文版)

The earliest rudimentary seals were leather straps wrapped around axles to retain animal fat lubrication—less than ideal and prone to leaks.

In the early 20th century, assembled leather seals in metal cases became common, enabling press-fit sealing in industrial machinery.

The Chicago Rawhide “Perfect Oil Seal”, made of leather within a metal housing, was patented in 1928 and widely adopted—by 1938, 93% of automotive equipment used it.

A major leap occurred post-WWII with the shift from leather to oil-resistant synthetic rubbers (like nitrile), and the advent of chemically bonded rubber-to-metal designs by the 1950s.

The 1960s introduced high-temperature elastomerssuch as silicone, polyacrylate, and fluoroelastomers; by the 1980s, seals featured integrated dynamic surfaces (cassettes) and multi-lip designs.

Current Development & Materials

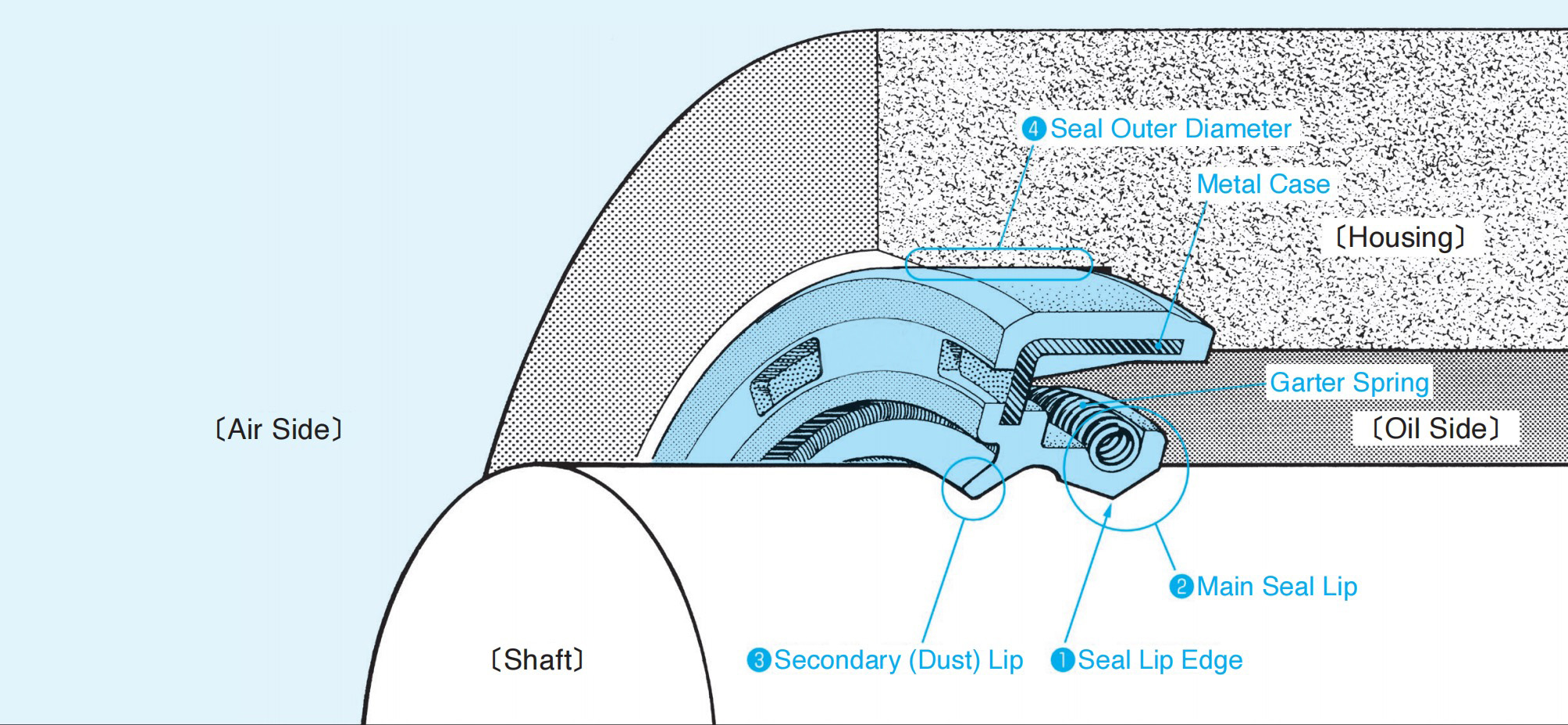

Modern radial shaft seals are comprised of:

A metal or rubber-covered outer case

A rubber or PTFE sealing lip

A garter springto maintain lip pressure, and sometimes a dust lip to guard against contaminants.

Common elastomers include NBR, FKM, ACM, HNBR, EPDM, etc., selected based on resistance to chemicals, temperature, and wear.

Industry standards guide design, dimensions, and testing—for example, ISO 6194and DIN 3760 are widely used specifications.

Leading companies such as SKF, Freudenberg Sealing Technologies, Trelleborg, Parker Hannifin, NOK, and John Crane continue to drive innovation and global expansion.

MKC&WUDE Oil Seal Industrial Co., Ltd. is a professional manufacturing, our team had experience in producing technology and design development more than thirty years. By using various kinds of vulcanization automatic equipment and new technology to provide high value oil seals for customers.

Through innovation, MKC&WUDE develops technology that strengthens the company’s position in the competitive market.

Future Outlook & Trends

Market Expansion:

The high-pressure radial shaft seals market is forecasted to grow from ~USD 866 million in 2024 to ~USD 1.12 billion by 2032, at a CAGR of 7.3%.

The broader radial shaft seals sector is thriving on innovations, customization, and sustainability.

Asia-Pacific dominates with over 40% market share, driven by industrialization and automotive growth.

Material & Tech Innovation:

Development of advanced elastomers, composites, and eco-friendly or bio-based materialsis on the rise.

Integration of smart technologies (IoT sensors, predictive monitoring)enables real‑time condition tracking to preempt failures.

3D printingand digital twin modeling facilitate rapid prototyping, customized geometries, and performance optimization.

Sustainability & Customization:

There’s a push toward low‑friction, energy‑efficient sealsand sustainable manufacturing, including recyclable and biodegradable solutions.

Businesses emphasize tailored seal solutions—precisely designed for specific machines and environmental requirements.

Get in TouchWe’re here to help. Contact us through:

+86-185 5046 4426

holly0426@126.com

最新动态

- 冬至临 暖意行:伍得人奔赴一线 不负每一份信赖 2025-11-07 14:23:08

- 苏州伍得机械配件有限公司闪耀2025年孔敬国际农业展会 2025-09-17 16:25:12

- 2025 年油封在中国市场数据洞察:规模,需求与竞争格局 2025-08-26 09:36:06

- 油封的发展历程:从雏形到现代工业的关键部件 2025-08-25 09:28:25

- 旋转轴唇形密封圈的发展历史与展望(英文版) 2025-08-07 14:02:30

- 恭喜蘇州伍得員工蔣紅玲順利通過香港大學IMC研究生專業畢業答辯 2024-09-18 09:26:19

- 蘇州伍得机械配件有限公司開通微信公眾號及抖音、微信視頻號推廣帳戶平台 2023-11-30 09:54:44

- 为中国农业机械发展注入米卡斯动力|台灣米卡斯希爾油封首次亮相国际农业机械展之產品篇 2023-11-02 14:15:58

- 为中国农业机械发展注入米卡斯动力 | 台灣米卡斯希爾油封首次亮相武漢國際农业机械展览会 2023-11-01 13:53:56

- 米卡斯油封 用于制造业 2023-05-25 16:15:14